Molino Dallagiovanna

Experienced in making flour since 1832, and the only mill in Italy that still washes the wheat with water, allowing the flour to have a better quality.

Our Story

Almost Two centuries of flour milling experience

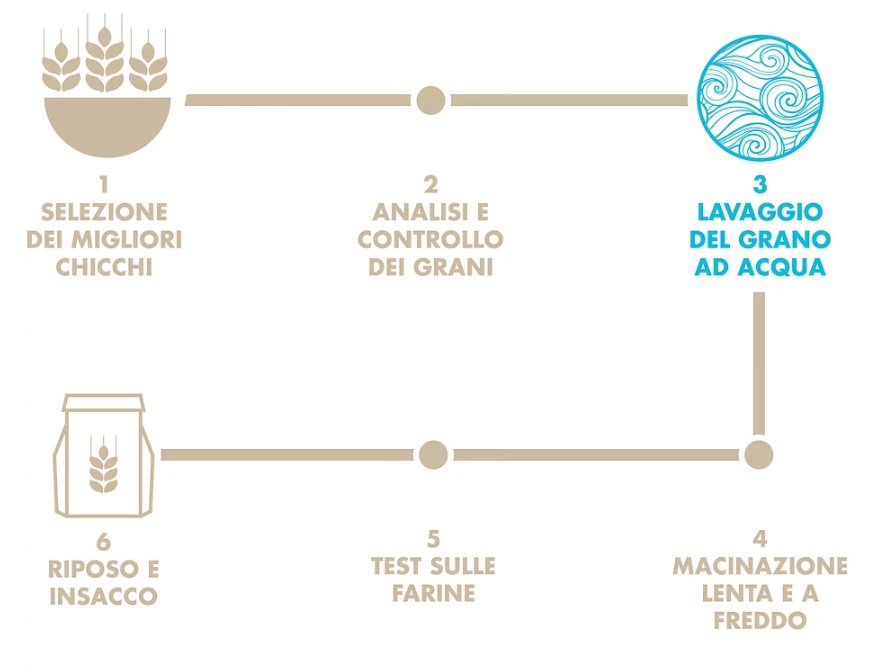

Molino Dallagiovanna was established in 1832 and has been a family business for six generations. It is located in Piacenza, the heart of Pianura Padana, the only location in Italy where soft wheat is grown. Today, Molino Dallagiovanna is one of the best producers in Italy of high-quality flour for professional use. Joining the highest level of research and production technology, with the passion and expertise for original, Italian food excellence. Molino Dallagiovanna is the only mill in Italy that wash all of their grains before milling.

Pierluigi Dallagiovanna, is personally responsible for the selection of the grains. Everything about their flour is special. Molino Dallagiovanna’s intuition in choosing the most suitable grains, their methods of analysis and research, and their combination of traditional processes and avant-garde machinery guarantees an outstanding finished product.

Flour Varieties

Year old company

Countries

leading innovators in the italian flour industry

Raw material Quality

The Dallagiovanna family personally selects only the finest quality grain, some of which are grown in a controlled supply chain. A grain passport is available which certifies the treatments carried out in the field during sowing. This guarantees product excellence.

The Laboratory

Research & development are essential to evaluate the quality, strength, elasticity, resistance and tenacity of each individual flour through analysis carried out with the latest technology. The task of a mill is not only to offer flour of the highest level, but also to obtain balanced, constant and safe products.

Cleaning & Washing

Cleaning is one of the key requirements to offer a superior quality flour, in fact Molino Dallagiovanna carries out first a dry cleaning, then they are the only mill to wash the grain. This allows Molino Dallagiovanna to eliminate all impurities and to soften the grains facilitating the milling.

Masters of taste

In Molino Dallagiovanna’s White Art Laboratory the flours are tested by their internal technicians and by important Masters from the Best Schools in Italy: Cast Alimenti, AMPI and other great industry professionals and international Chefs – who with their art and experience, are essential for the continuous improvement of production.

Water is Life

Superior Flour from washed wheat

The washing of the grain allows Molino Dallgiovanna a unique production process. This process has been eliminated from the other mills as it is a very expensive part of the process in terms of money and time. This has now become one of Molino Dallagiovanna’s strengths, as well as a distinctive feature.

Only the power of water, combining modern technologies with the ancient milling art of washing grains which allows Molino Dallagiovanna to create superior flour. Flour from washed wheat.

The process of washing the wheat with water is crucial for the realisation of a superior flour. This distinctive technique is done in the lavagrano (grain washer) machine. The lavagrano is a machine used for cleaning grain in a closed tank with jets of water from underneath the grain.

By only spraying the wheat with water does not allow allow the grain to soften properly which facilitates in the correct breaking down of the kernels during the grinding phase – the grain would peel off less easily and there would not be a correct division of the wheat (bran, germ, small bran etc.)

By washing each variety of wheat individually, the lavagrano allows Molino Dallagiovanna to absorb the right amount of water that grain requires to be softer and ready for the milling phase and eliminates impurities.

This process of washing the wheat, and slow & cold grinding, allows Molino Dallagiovanna’s flours to be whiter and their scent of wheat, instead of inferior flour products which tend to be grey and smell of the paper sack.